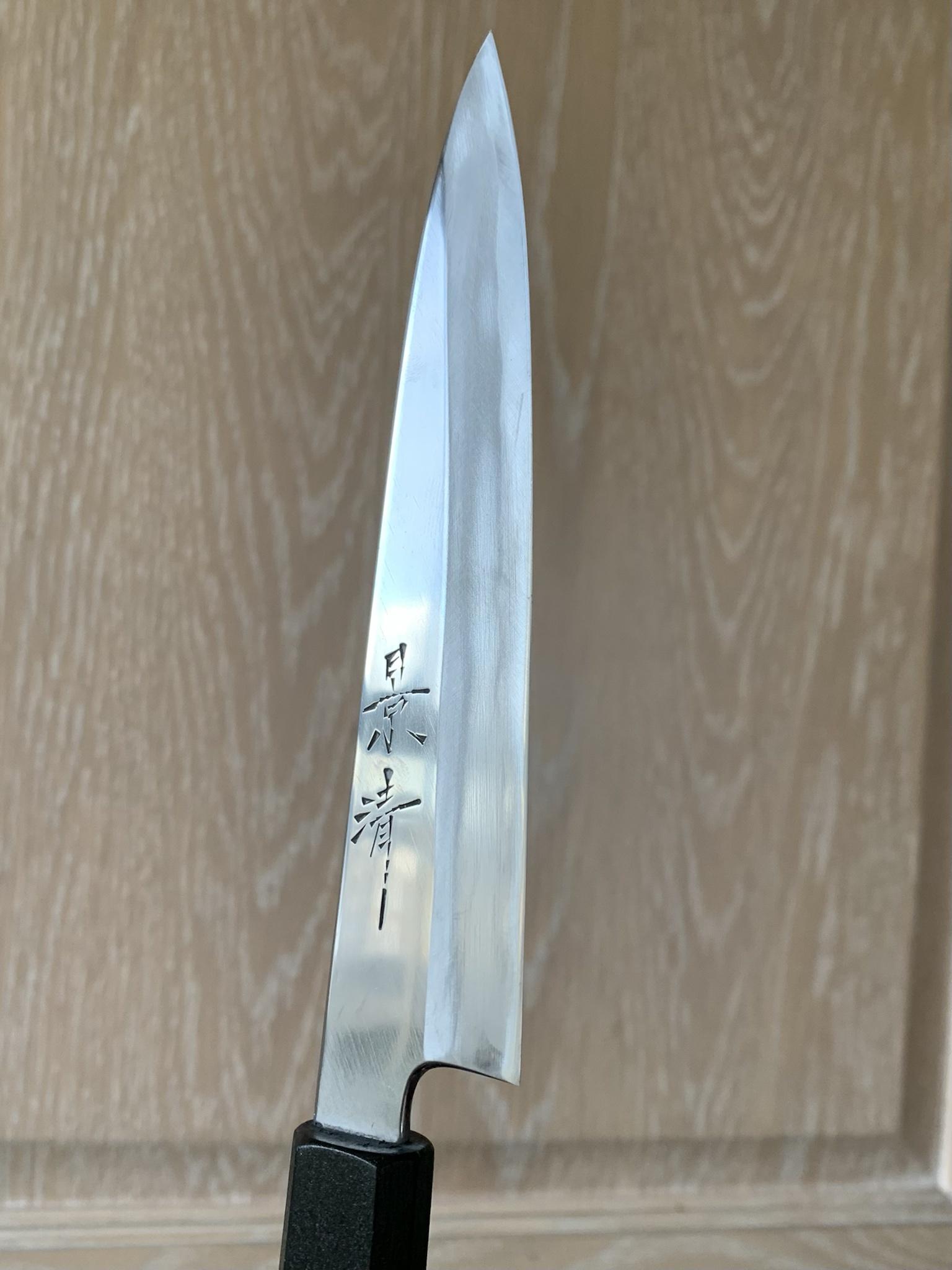

I worked on my wrought clad/52100 @HSC /// Knives Gyuto some more.

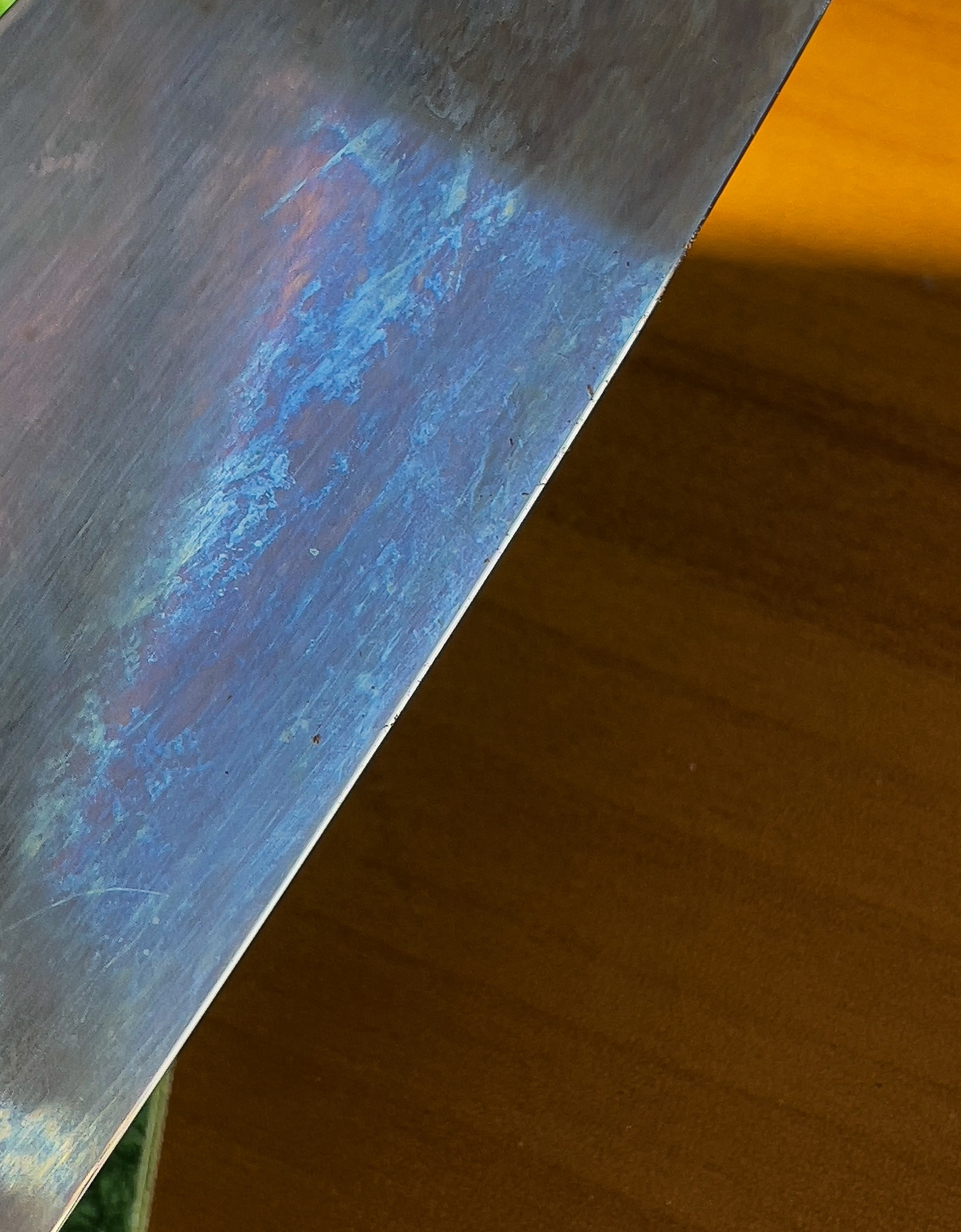

Progression was SG 500, SG 4k, 1k sandpaper, 1 micron diamond paste. Followed by etching (a mix of balsamic vinegar, old coffee and coffee made with white vinegar). Wrapped some paper towels around the blade, and poured the mixture over the blade several times. Then let it sit for 20 minutes. I then gave it a vigorous washing with hot water, soap and the soft side of a sponge. I think it turned out pretty good?

Progression was SG 500, SG 4k, 1k sandpaper, 1 micron diamond paste. Followed by etching (a mix of balsamic vinegar, old coffee and coffee made with white vinegar). Wrapped some paper towels around the blade, and poured the mixture over the blade several times. Then let it sit for 20 minutes. I then gave it a vigorous washing with hot water, soap and the soft side of a sponge. I think it turned out pretty good?